Their power to deal with a multitude of operations and resources will make them indispensable in modern day manufacturing.

The Resource changer is an additional critical component, liable for routinely swapping out tools over the machining method to reduce downtime.

In essence, the Software changer is an important element that contributes to maximizing the abilities of a CNC machining center, rendering it an indispensable asset in modern-day manufacturing procedures.

CNC lathes rotate spin the workpiece while in the spindle (in lieu of the mill Resource head in mills), with a hard and fast cutting Device slicing chips from your spinning element.

Focused routine maintenance monitor – easy Guidelines be certain fast recovery if, for example, zero details are dropped due to incorrect operator enter

The Instrument journal is surely an integral Element of the ATC system. It stores several cutting tools like close mills, drills, plus much more, delivering a central repository for the tools required within the machining method.

Machining procedures make chips and demand cooling to take care of tool lifestyle and aspect high quality. The chip and coolant dealing with system manages these aspects, collecting chips by means of chip conveyors and furnishing the necessary coolant to the cutting location.

Then along came the main personal computers. These early personal computers, although primitive, could make their own punched tape determined by selected inputs. This substantially greater the speed at which commands may be developed.

Make contact with us to get additional information regarding ROBODRILL, or to request a value quote. We are going to be joyful to reply any questions you'll have, simply click on under to get rolling.

Understanding the capabilities and constraints from the spindle is important for maximizing efficiency and attaining optimal results in CNC machining programs.

Control Panel: Operators enter the G-code into your machine’s control panel. Fashionable machining centers read more frequently attribute consumer-friendly interfaces for less complicated Manage.

Dependant on these customized Guidelines in the G-code file, the machine may be programmed for actual speeds, positions, and might change out tools for different elements of the process to find the best success.

The VMC is recognized for its flexibility in dealing with different resources like metals, plastics, and composites with high accuracy and efficiency. Its design and style enables operators to work on multiple sides of the workpiece without the need to reposition it constantly.

By being familiar with how these elements purpose alongside one another, companies can enhance their production procedures and obtain higher amounts of productiveness. It is important to consider Each and every element's capabilities and maintenance requirements to maximize the general performance of the machining center.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Rick Moranis Then & Now!

Rick Moranis Then & Now! Jason J. Richter Then & Now!

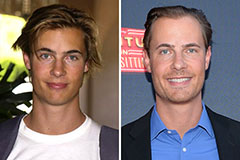

Jason J. Richter Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!